要优化氮气覆盖,要考虑的因素包括:

- 最具成本效益的供应模式:气体,液体或现场制气

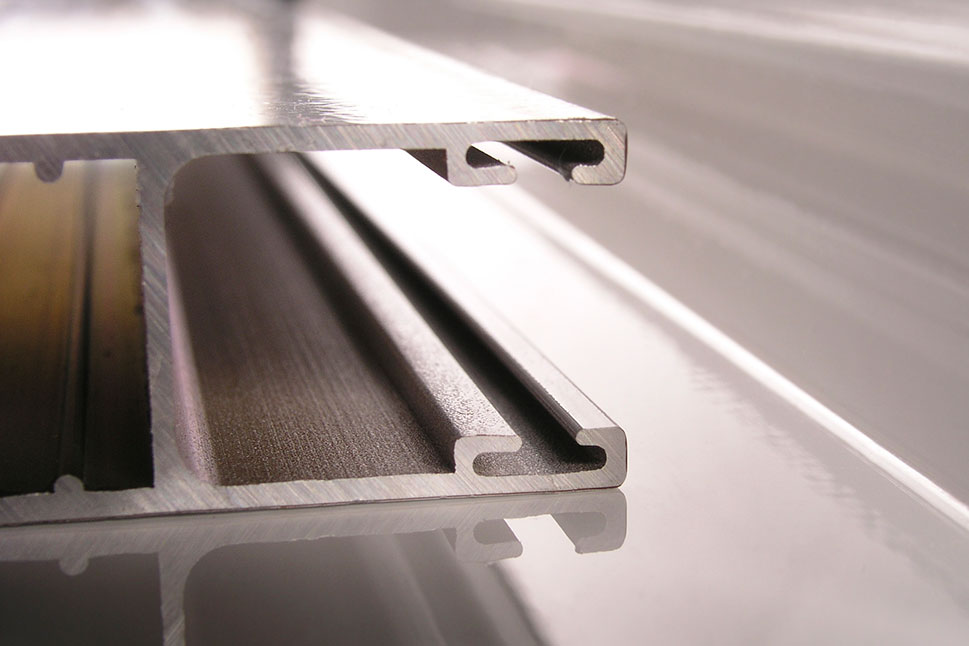

- 氮气导入位置:模背板,支撑,压板/罐

- 如何确定最佳氮气流速

- 工具开槽方式和工具的稳定连接

- 设备问题,比如尺寸过小的软管/接头,最小流量控制和流量测量

- 氮气泄漏

- 多孔模具中的氮气分配不良

- 挤压多少形状和合金

- 实心,中空或多孔模具

- 单模或双模滑块

- 从其他具有不同开槽,连接等的挤压机购买工具。

- 氮气流量不足,无法提供适当的冷却和惰化

Helping Aluminum Producers Optimize Production and Economics

Light Metal Age’s Ann Marie Fellom sat down with Air Products’ Russell Hewertson at the ALUMINIUM USA trade show in Detroit, Michigan, as part of the magazine’s interview series with notable members of the aluminum industry. In his interview, the Americas Commercial Technology Manager at Air Products discussed the importance of close collaboration with aluminum producers to help them optimize their operation through our expertise, gases and technologies.

Check out our brief video excerpts from the full interview that answer some frequently asked questions.

您可以信赖空气产品公司的专业知识…

我们的应用工程师可以帮助您优化挤压工艺中的氮气性能。